Contents

Your band saw is a very powerful tool that will help you cut along curves, straight lines, and all kinds of irregular shapes. With the right blade in place, your band saw can cut through a diverse range of materials. Discover what type of band saw blade to use for your next home improvement project.

However, all this will only be possible if you have the right band saw blade. Once you understand all there is to know about band saw blades, there is nothing your band saw cannot do.

Read on to find out what type of band saw blade to use in this ultimate guide!

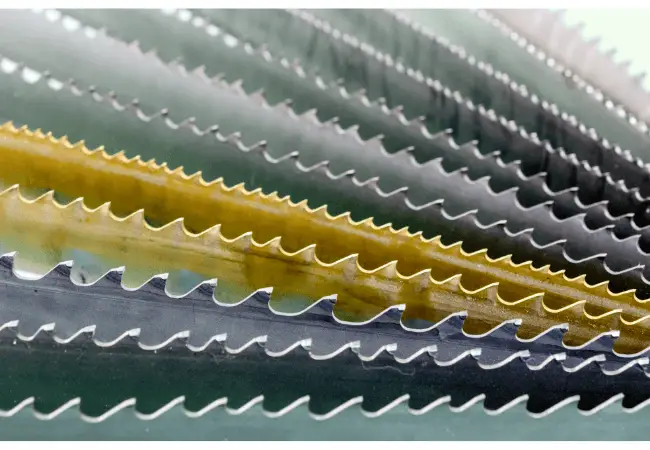

Band Saw Blade Types

There is a wide variety of blades that you can choose from for your band saw. They are classified according to the blade’s size, tooth form, and material. Learn what type of band saw blade to use for different types of wood.

Teeth Per Inch (TPI)

The TPI or teeth per inch provides essential information about band saw blades; this is one of the elements that determine the final look of the cut. The TPI gives the number of teeth on one inch of the band saw blade, as evident by the name.

To choose a good blade for general use, select one with a TPI of 6 to 10.

Fine or Coarse Blades

A blade is considered fine or coarse based on the number of teeth on the blade. A blade with few teeth is considered rough or coarse and is likely to have a TPI of 2 to 6.

Such blades are suitable for cutting quickly through soft materials, though the cuts are more significant. However, the blade cannot make precise, accurate cuts because of the lower number of teeth.

Carpenters and woodworkers often need to make such cuts; this is why they are likely to opt for a fine blade instead. A fine blade generally has more teeth, often with a TPI of 14-24. The objective of these finer blades is to make precise cuts.

Another vital use of fine blades is cutting hard materials such as metal or thin sheets.

Fine blades have some disadvantages too. You cannot use the higher number of teeth for more significant cuts or quick cutting because of the higher number of teeth. Additionally, these fine blades and their large teeth can become dull more quickly.

Blade Selection Guidelines

- For softwood, use a coarse blade with 2-6 TPI.

- Use a general-purpose blade with 6-10 TPI for hardwood and aluminum.

- For steel, use a fine blade with 10-18 TPI.

- For thin sheets, use a fine blade with 14-24 TPI.

When choosing the right blade for a thin sheet, remember that you need at least 2-3 teeth to be in contact while cutting; this means that for a ⅛ inch sheet, choose a blade with a TPI of 16 or more for an accurate cut.

Every blade can be helpful in different situations; this is why it is recommended that you keep both fine and coarse blades with you, which will help you use the band saw on a wide range of projects.

Blade Forms

Blade form is another important concept. It refers to the design of the teeth and the space between the teeth. The following are the usual forms:

Regular Tooth Blades

Blades with regular teeth are also known as standard blades. They have a conventional tooth design and generally a zero rake angle.

These blades are designed to provide accurate cutting of soft materials such as thin sheets and softwood. They are also suitable for general-purpose cutting and contour cutting.

Skip Tooth Blades

The skip tooth blade is the second type of band saw blade. These blades have no rake angles and flat gullets. The shallow gullets on these blades are designed to cut large sections.

You can use them to cut a diverse range of materials, such as different kinds of plastics, wood, and metals. Skip tooth blades have wide gullets that cut through soft materials such as wood and do not cause clogging.

Skip tooth blades generally make cuts that are less precise than regular blades. While they do lack precision, these blades make up for speed and the capacity to do large amounts of cutting without clogging.

Hook Tooth Blades

The last kind of blade is the hook tooth blade. The names show that these blades have a design philosophy similar to hooks. The positive rake angle is usually 10-degree; this enables the blades to dig into your material quite profoundly.

Deep gullets on these blades enable them to take deep bites from the material on every cut. The best time to use the hook tooth blade is to cut materials that produce non-continuous chips, like cast iron.

The downside of the hook tooth blades is the inability to make accurate, minor cuts.

Variable Tooth Blades

Variable tooth blades have varying gullet depth and varying set angles. Because of these features, the variable tooth blades have reduced vibration while cutting.

Variable Pitch Blades

This type of blade has groups of varied pitches throughout the blade length. A variable pitch blade with 6-10 TPI will have a TPI of 6 followed by a TPI of 10 teeth.

Using a constant set and pitch blade produces a harmonic vibration during sawing, which is likely to decrease the saw’s life, give a poor finish, and increase noise pollution. Using a variable tooth blade gives you a different pitch and gullet depth, breaking the rhythm, eliminating any harmonic vibrations.

Blade Selection Guidelines

- Regular tooth blades have a standard tooth form and are suitable for general use.

- Hook tooth blades have a deep gullet and positive rake. They are good for faster cutting.

- Skip tooth blades have a shallow flat gullet with no rake and are suitable for slower, smooth cutting.

- Variable tooth blades have varying gullet depth and pitch and are appropriate for vibration reduction.

Set Of Teeth

The blades’ teeth are bent or offset slightly towards the right or left so that the blade has clearance towards the rear end; this is called a tooth set, which results in a wider cut than the thickness of the blade or kerf width.

Tooth sets have various types for different applications. These include the following:

Alternate Tooth Set

One tooth offsets to the right and the next to the left in an alternate tooth set.

Raker Tooth Set

The raker tooth set has three sequences of teeth. The first is to the left, the next to the right, while the third is straight or unset.

Blade Materials

Blades are made from various materials, which is an essential factor to consider.

Some of the primary materials include the following:

Carbon Steel Blades

These blades are used most often for woodwork. In addition to being quite inexpensive, they provide sufficient hardness for cutting soft materials, including plastic, wood, or plywood.

Bi-metal Bandsaw Blades

These blades are made from two separate layers of metals, generally HSS and spring steel. The spring steel part of the blade gives sufficient flexibility, whereas the high-speed steel or HSS on the cutting tip gives you the hardness needed for cutting through the hard, more rigid materials.

Most people who work in the metalwork industry use bimetal steel blades to cut cast iron, tool steel, channels, structural steel, and pipes. You can also use them to cut through non-ferrous material, such as brass, aluminum, bronze, copper, or bronze.

Bi-metal band blades generally retain their cutting edges for longer and are likely to increase your band saw’s life by 5 to 10 times compared to carbon steel blades. On the downside, they are more costly. However, in the long run, their cost-effectiveness is more.

Blade Width

The width of a blade used with a band saw is an essential element. The general guideline for making this choice is as follows:

Cut Off Sawing

For cut-off sawing, choose the widest blade that you can. The reason is that a wider blade will give you a straighter cut, making the feed faster.

Contour Sawing

Contour sawing includes arcs and other irregular shapes that you may cut. In this case, you have to consider the minimum radii that you have to cut. A narrow blade will enable you to cut a smaller radius though it may be likely to break rather easily. Choose the widest blade you can use, given the particular cut you have to make.

Possible Problems You May Have With Your Band Saw Blade

Blade selection is an important decision whether you plan to use your band saw to cut wood or metal. The wrong selection can ruin your band saw.

If your blade becomes dull too soon, check the speed. If you run the blade at a rate higher than the optimum level, the cutting teeth can lose their sharpness soon. Simply reducing the speed will solve this problem.

Another solution is to increase the feed. Light feed pressure can also make the blade dull.

You may experience clogging as the gullets get loaded fast if there is limited space for metal chips or sawdust. To avoid this, use a coarser blade that has a deep gullet.

Premature blade breakage may be caused because of several reasons. However, the main reason is improper tuning. Make sure that you load the blade properly on the wheels and align. Also, check that the blade has the correct tension.

Conclusion

Now you have all the essential information you need about the types of blades to use with your band saw. You can simply walk into the local hardware store, choose the right blade, and start using your band saw!

Related Article

Leave a Reply