Don’t have a lot of free time? Not a problem. Just read this brief primer on how to operate a bandsaw and become a pro in no time!

Contents

A Few Important Pointers

We’ve compiled a list of bandsaw tips and techniques that you should be aware of — maybe you can apply them during your next session.

Keeping that in mind, let us begin with the very first.

Understanding Different Types of Blades Used in A Band Saw

Considering that different materials need distinct blades, it’s critical to understand the materials you’ll be interacting with the most so that your edges are tailored for that specific job.

Skip, hook, and regular-tooth blades are the three most frequent varieties of blades.

Regular tooth blades are all-purpose; therefore, you’ll find them everywhere since they’re commonly acknowledged through most materials. Hook-tooth edges are more significant than standard blades and have a hollower tube making them ideal for quick cuts.

Because of the gap between tooth surfaces on the blades, skip-tooth blades are ideal for cutting plastics, spruces, and non-ferrous materials.

The Importance of Replacing Throat Plates

You want to ensure that you get good cuts but never at the expense of your hands, correct?

A neck plate is the most excellent way to protect both the blades and you from possible harm. Most bandsaws include a throat plate; however, try purchasing a polycarbonate throat plate if yours does not come with one.

A thermoplastic throat plate is used because it will not harm the blade if they come into touch. These plates are also reasonably priced, which is a plus.

Repair these throat plates regularly, particularly if they are broken or exhibiting symptoms of weakening.

What is the explanation behind this? You are avoiding a stockpile of wood from collapsing and minimizing splitting.

Always Remember to Use the Bevel

For many people, the bandsaw’s bevel is an underused component. That being said, some people do not see the necessity for this function.

However, when utilized appropriately, the bevel’s tilting function positively impacts the quality of your output.

With the option to recline to the side of the tabletop at a 45° angle, you have more flexibility in the kind of cuttings that you can make.

Put On the Blade Guards to Prevent Unnecessary Damage

You must increase the position of your blade shield so that it is just well above the object that you’re chopping.

What’s the deal with this proximity? More significant gaps between the cover and the blade will damage the blade and generate unnecessary strain. This phenomenon increases the likelihood of the blades breaking, which is something you don’t want.

What is the ideal amount of spacing between the two? A good elevation for the blade shield is anything between 1/4 and 1/8. This length is good enough to reduce blade tension while not interfering with the cut line.

Setting your blade guards after each cut will ensure that your bandsaw performs optimally in every usage.

Clean the Bandsaw Blades Regularly

Most people recommend washing your bandsaw blades after each usage, but this may be time-intensive and, simply, unnecessary.

Monthly or bi-monthly washes are good, but it also depends on how frequently you use your bandsaw, the materials you cut, and the blades you’re using.

Particular blades accumulate resin and crud more frequently than others. Changing the blades is an ideal opportunity to clean them.

When it comes to what to use as a blade cleaning, you have a few alternatives. Oven cleaners and degreasing agents are excellent for this.

You may also wash your blades with an essential, uncomplicated rinse in soapy water – the cheapest and most efficient way.

Setting Up the Bandsaw

The blades of a band saw should be properly fitted for it to cut well. The process of setting up is the most challenging element of using a bandsaw, but it’s not that difficult.

- Disconnect the saw and remove it from its cabinet.

- Loosen the blade tensioner, wrap the blades onto the bottom roller, and then put it onto the edge, teeth facing down towards the top of the table.

- Adjust the tensioner only enough to remove the slack from the blades.

- Hand-rotate the top wheel and set the tracking knob (typically located at the rear of the entire disc) until the blade falls roughly in the center of the wheels.

- Then, tighten the blade according to the manufacturer’s instructions. The amount of tension exerted is determined by the breadth of the edges.

Band saws depend on support above and below the table to trace and maintain the wheels’ razors. To commence, make sure that none of the guides are in contact with the blade. Then, proceed as follows:

- Start from the top, release the locking bolt on the blade, and position the thrust bearing as thinly as possible.

- Then, go to the guiding blocks on the blade’s side.

- Release their locking nuts and move them away from the blade to roughly the width of a sheet of paper.

- Position the guide blocks to become even with the gaps in between the teeth.

- Most band saws feature a series of guides under the table that are comparable to this. Adjust them similarly to how you adjusted the top guidelines.

- Finally, make sure the table is parallel to the blade. Unscrew the locking knobs under the table. Set the table square with a combination square, then lock the bolts.

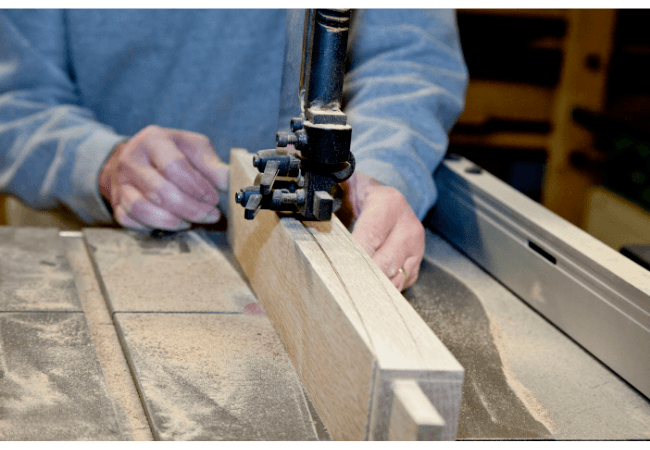

Making Straight Lines Using Your Bandsaw

Have a bandsaw but facing trouble cutting a straight line? Take the following steps:

- Raise the blade cover to roughly half an inch above the body before making any incisions.

- You’ll have to double-check that the blades are cutting straight to the fence every time you replace it.

- Take a 2-foot-long scrap with a demarcation line along the center perpendicular to one edge.

- Cut the line as precisely as you can by sight.

- When the scrap is correctly aligned with the blades, you’ll feel like you’re cutting straight without needing to make any significant modifications.

- Pause the saw and turn it off while securing the workpiece to the table.

- Label the surface with a marker along the border of the scrap whenever the blade comes to a halt.

Loosen the screws that hold the fence in place, align the bar with that line, and tighten the bolts again. That is the fence setting parallel to the blade. You may adjust the wall as required to change the breadth of your cut.

If your saw lacks a fence, you may purchase aftermarket ones or attach a straight bit of plywood to the tabletop.

The Final Takeaway

The more you use a bandsaw, the more comfortable you’ll get. All the tips and tricks above will help you ensure that you get the best out of it!

Never neglect any of your safety gear. A mishap takes a moment to occur. Clean your bandsaws at timely intervals to avoid any gunk from accumulating.

Follow all the safety tips, and happy chopping!

Related Article

Leave a Reply