The air compressor is a vital device that has become part of our daily lives. Understand that we are living in an era of constant development in the industrial sector. The air compressor installation guide will, therefore, come in handy whether you are a professional or DIY enthusiast.

This article is designed for anyone who is having trouble running their air compressor unit. You will find everything you need to know about air compressors in this comprehensive guide.

Contents

About Your Air Compressor

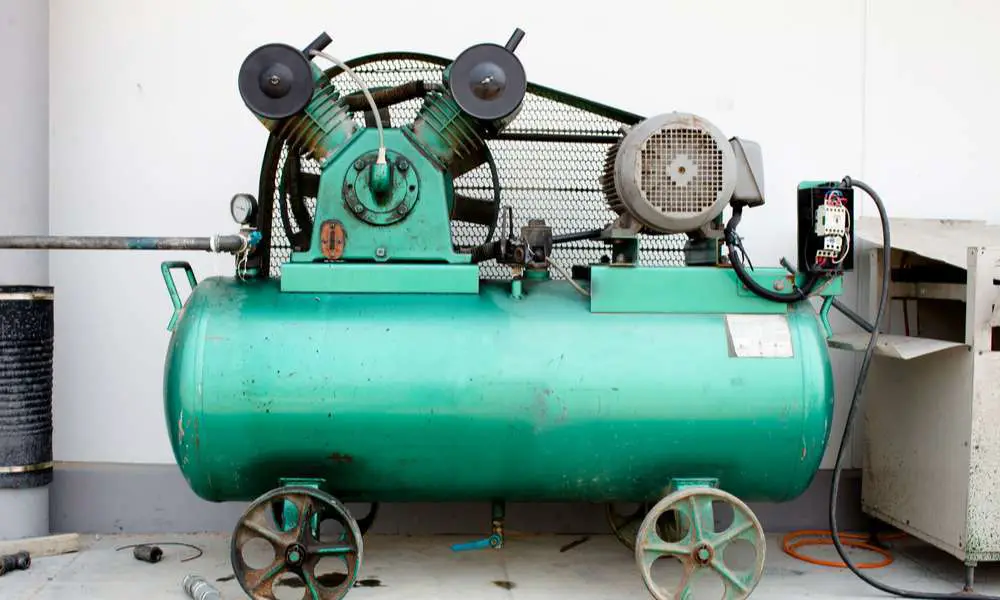

Before you can install and use your machine, it would help if you understood some of the basic components.

The Air Tank

This is the component that stores all the compressed air. Note that the air tank can either be horizontal or vertical depending on your model. They also come in different capacities and sizes to help you complete different types of projects. Understand that the stored air gets the opportunity to cool since the tank is sized at about 6-10 times the system flow rate.

The Motor

You will usually find the motor placed above your tank. Note that this component works similarly to your car engine. It powers the compressor pump while the flywheel fan cools the pump during a project.

Regulating Parts

The regulating parts include the various valves and the manifold kit. The manifold kit needs to have two gauges that show pressure outside and inside the tank. Note that all the gauges and valves need to be functioning correctly to get the most from your air compressor. Pay close attention to the drain valve, check valve, and safety valve.

Basic Installation Procedure

Now that you understand the different components of your air compressor, we need to get started on the basic installation guide. Below is a step-by-step instruction to ensure you get value for your money and get long-lasting services.

Step 1: Choose a Suitable Location

Before we can begin setting up your air compressor, you must identify where to place the machine. Understand that the location will have a significant impact on how the machine works. Experts advise that you install your air compressor in a clean and dry area.

Note that your device can cause fire and electrical accidents when installed in a bad location. Such unfortunate accidents are avoidable by choosing a spot that is suitable for your machine. Survey the entire location and find a suitable place for installation.

Step 2: Plug the Air Hose

Contrary to what most people think, the air hose is never included in the air compressor price. You will have to purchase it separately. Understand that the type of air hose is dependent on the type of air compressor that you have. You should, therefore, take your time when purchasing to ensure you get a suitable model. Ensure you do the fittings appropriately to avoid any air leaks with your configuration.

Step 3: Attach the Accessories

When you purchase a new compressor, it comes fully assembled. You will not have to worry about the air filter, air dryer, air tank, and electric motor. However, understand that there are a few components that you will need to plug in by yourself.

The good news is that plugging in these small parts is not a challenging task. Read the user manual to understand where everything goes. Note that your manual should give you a clear description of where to install all the different accessories. Remember to carefully attach these small parts because this will dictate the efficiency of your machine.

Step 4: Start Your Machine

Start by turning the regulator knob to the left side. Note that the gauge should read zero PSI before we can start powering out the compressor. Turn on the machine and check for any air leakages before moving on to the next step. Do not worry about any loud noises when powering on the air compressor.

The machine will, however, instantly stop when the air pressure gets to 150 PSI. You can then adjust the air pressure using the regulator to suit the connected tool. Understand that different tools will need different amounts of air pressure.

The Importance of proper setup

Proper installation will guarantee that you get long-lasting services from your machine. Note that having a high-end machine is useless without the proper installation. An air compressor will do you no good if you can’t install it correctly.

Understand that the proper installation of your air compressor makes all the difference. You will get good quality services when working with different types of air tools. Note that proper setup will also guarantee a reliable, safe, and energy-efficient system.

Important Tips

Choose a Location that is Close to a Power Source

When setting up your system, you have to consider the distance from the power source. Moving your air compressor around is not going to be an easy task. You will also get to save a lot of money on energy and piping when you choose a location close to the power source.

Check the Voltage

Ensure that the voltage on your power source matches that of your air compressor. Your machine comes with a manual that indicates the recommended voltage. Note that using a higher or lower voltage leads to serious damages. You will get long-lasting services from your machine when you match the voltages.

Always Take Safety Precautions

Safety is always a priority when working on any kind of project. You should never forget to wear your protective items when working with your air compressor. Turn off the power once you complete a project to avoid any accidents in the workplace.

How to choose the best Air compressor

Choosing an air compressor is never as easy as it might look. Understand that there are several features that you must consider before making a purchase. In this next section, we will highlight some of the basic things that you must consider when buying an air compressor.

1. Understand the Types of Air Compressors

There are two basic types of air compressors in the market: piston and portable air compressors. The portable air compressors are suitable for DIY enthusiasts while the piston models are best for professionals. The two-stage piston air compressors pack a lot of power and are suitable for different types of projects.

2. Analyze your Air Tools

Are you going to power pneumatic tools or power machinery using your air compressor? The answer to this question will help you find a suitable air compressor. A compressor with a tank is preferable when you require a high flow of compressed air. However, a portable compressor that doesn’t include a tank can be sufficient for filling a tire and airbrushing.

Related Reading : 9 Best Air Compressor For Home Garage 2021

Conclusion

Installing an air compressor is simple and straightforward once you understand all the steps. However, this doesn’t mean that you should skip reading the manual once you purchase your compressor. Note that the user manual contains all the basic information to guarantee you get long-lasting services from your machine.

Ensure you purchase an air compressor that can work with all your air tools. Note that different tools will need specific air pressures to give you the best results. Buy a compressor that can effectively serve all the tools in your home or workplace.

Leave a Reply